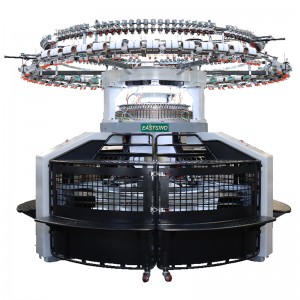

20inch Double jersey circular knitting machine

Machine Specifications:

①Diameter: 20 inches

Compact yet powerful, the 20-inch size ensures high efficiency in fabric production without requiring excessive floor space.

②Gauge: 14G

The 14G (gauge) refers to the number of needles per inch, suitable for medium-weight fabrics. This gauge is optimal for producing ribbed fabrics with a balanced density, strength, and elasticity.

③Feeders: 42F (42 feeders)

The 42 feeding points maximize productivity by enabling continuous and uniform yarn feeding, ensuring consistent fabric quality even during high-speed operation.

Key Features:

1. Advanced Rib Structure Capabilities

- The machine specializes in creating double jersey rib fabrics, known for their durability, stretch, and recovery. It can also produce variations like interlock and other double-knit patterns, making it suitable for diverse fabric applications.

2. High-Precision Needles and Sinkers

- Equipped with precision-engineered needles and sinkers, the machine minimizes wear and ensures smooth operation. This feature enhances fabric uniformity and reduces the risk of dropped stitches.

3. Yarn Management System

- The advanced yarn feeding and tensioning system prevents yarn breakage and ensures smooth knitting operations. It also supports various yarn types, including cotton, synthetic blends, and high-performance fibers.

4. User-Friendly Design

- The machine features a digital control panel for easy adjustments to speed, fabric density, and pattern settings. Operators can switch between configurations efficiently, saving setup time and improving overall productivity.

5. Robust Frame and Stability

- The sturdy construction ensures minimal vibration during operation, even at high speeds. This stability not only extends the machine’s lifespan but also improves fabric quality by maintaining precise needle movement.

6. High-Speed Operation

- With 42 feeders, the machine is capable of high-speed production while maintaining uniform fabric quality. This efficiency is ideal for meeting large-volume manufacturing demands.

7. Versatile Fabric Production

- This machine is suitable for manufacturing a variety of fabrics, including:

- Rib fabrics: Commonly used in cuffs, collars, and other apparel components.

- Interlock fabrics: Offering durability and a smooth finish, perfect for activewear and casual clothing.

- Specialty double-knit fabrics: Including thermal wear and sportswear.

Materials and Applications:

- Compatible Yarn Types:

- Cotton, polyester, viscose, lycra blends, and synthetic fibers.

- End-Use Fabrics:

- Apparel: T-shirts, sportswear, activewear, and thermal wear.

- Home Textiles: Mattress covers, quilted fabrics, and upholstery.

- Industrial Use: Durable fabrics for technical textiles.