Double Jersey Circular Knitting Machine

FEATURES

With wonderful materials,excellent thermally balanced machine frame is made for body size double jersey circular knitting machine.

Materials from Japan,Cams are dynamically optimized and precisely produced for body size double jersey circular knitting machine

High tempered cylinder and every dial is always ready for body size double jersey circular knitting machine

Precise electronic mechanical synchronization of body size double jersey circular knitting machine.High speed machine of running without vibration.

YARN&SCOPE

Double Jersey Circular Knitting Machine knit fabrics can be used to vest, T-shirt, sportswear,fitness suit and swimming suit.

DETAILS

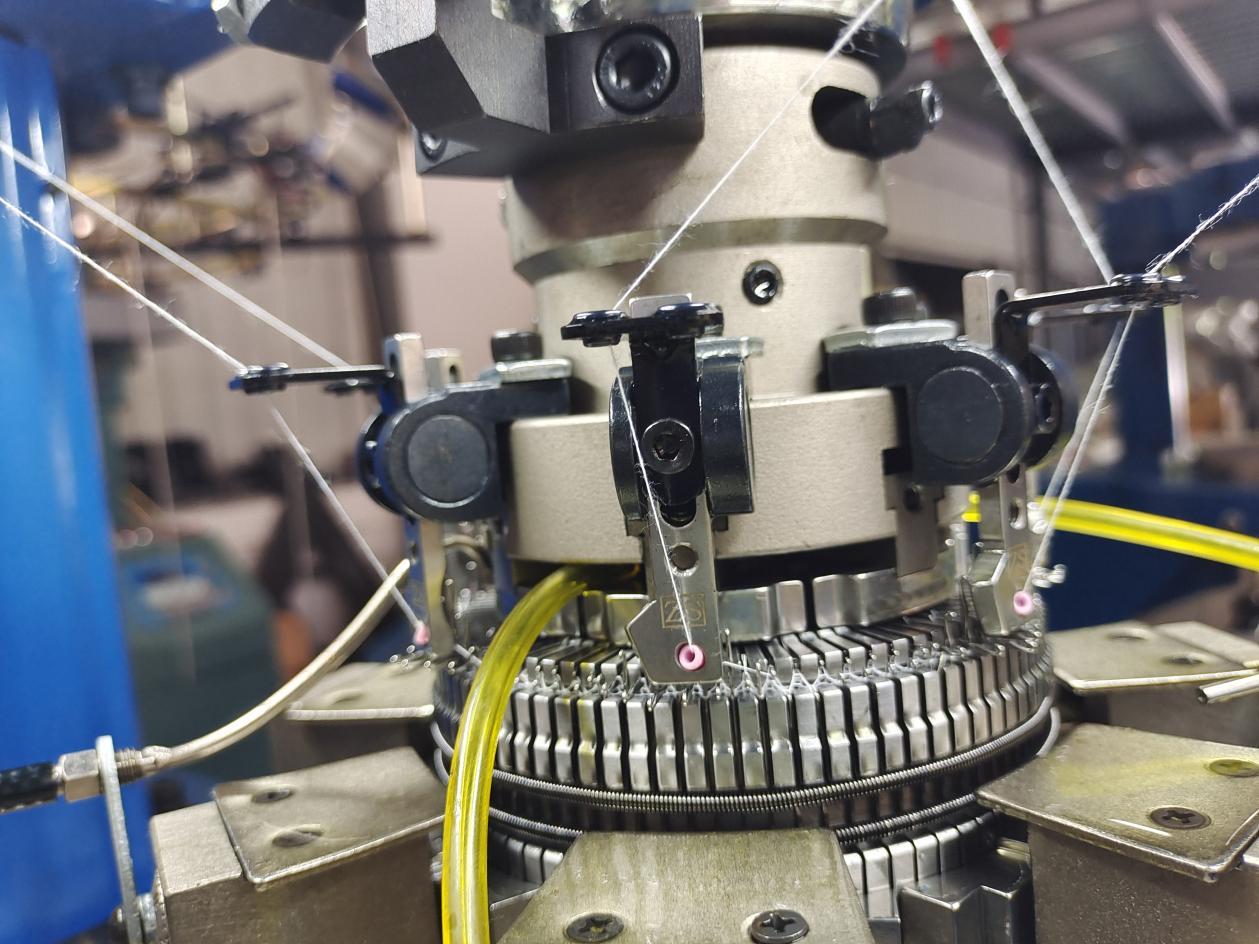

Double Jersey Circular Knitting Machine rotate in a single direction, and the various systems are distributed along the bed circumference. By increasing the diameter of the machine, it is then possible to increase the number of systems and therefore the number of courses inserted per each revolution.

Today, large-diameter circular machines are available with a number of diameters and systems per inch. For example, simple constructions such as the jersey stitch can have up to 180 systems.

The yarn is taken down from the spool arranged on a special holder, called a creel (if placed beside Double Jersey Circular Knitting Machine), or a rack (if placed above it). The yarn is then guided into the knitting zone through the thread guide, which is typically a small plate with a steel eyelet for holding the yarn. In order to obtain particular designs such as intarsia and effects, the machines are equipped with special thread guides.

HIGH COST-EFFECTIVE POSITIVE FEEDER.NEO-KNIT makes a great change on its material, technology and appearance, providing a new and high performance feeder for Double Jersey Circular Knitting Machine.

Aluminum alloy chassis ensures high distortion and corrosion proof LED light gives long life cycle and clearly visible from any operator position.Electrostatic prevention design avoids dust accumulation for Double Jersey Circular Knitting Machine.

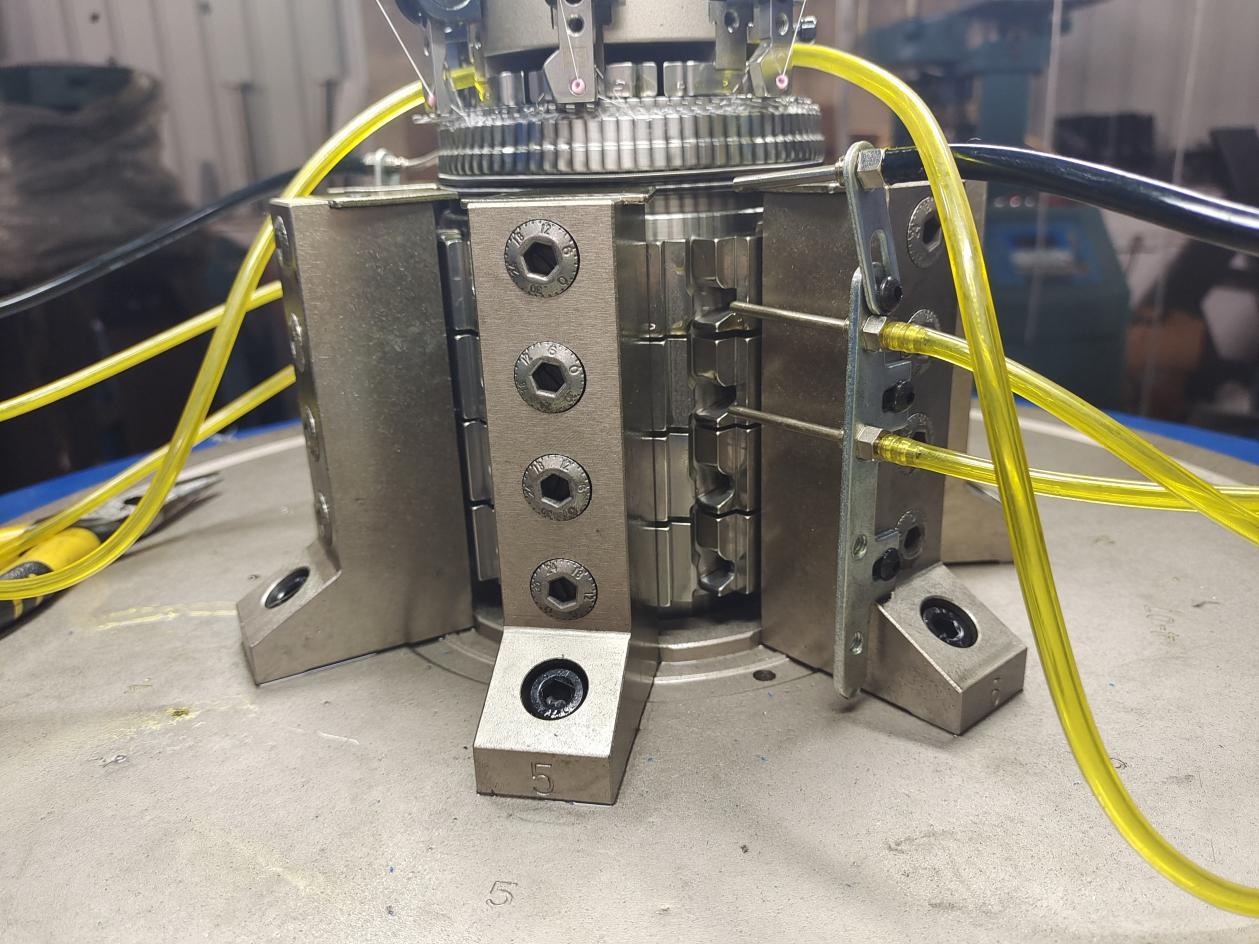

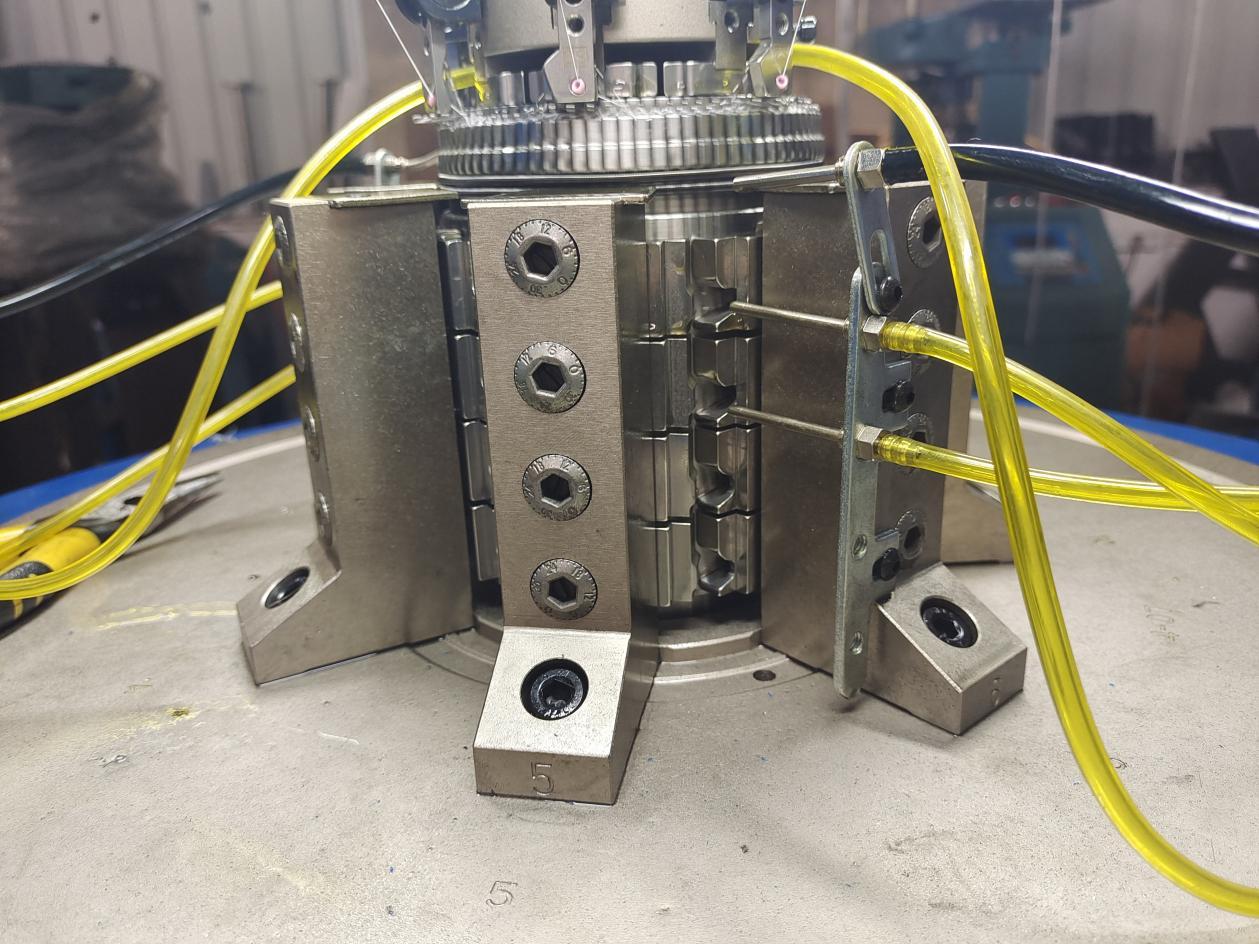

PULSONIC 5.2 PRESSURE OILER.Optimum lubrication for needles and lifters The PULSONIC 5.2 lubrication system precisely meters a small amount of oil per pulse to ensure that oil is only distributed to the points required. It is possible to individually program the amount of oil fed to each lubrication point. The system greatly reduces oil consumption. The external surface of the knitting machine remain dryer and the number of oil spots on the knitted fabric is greatly reduced.

DETAILS

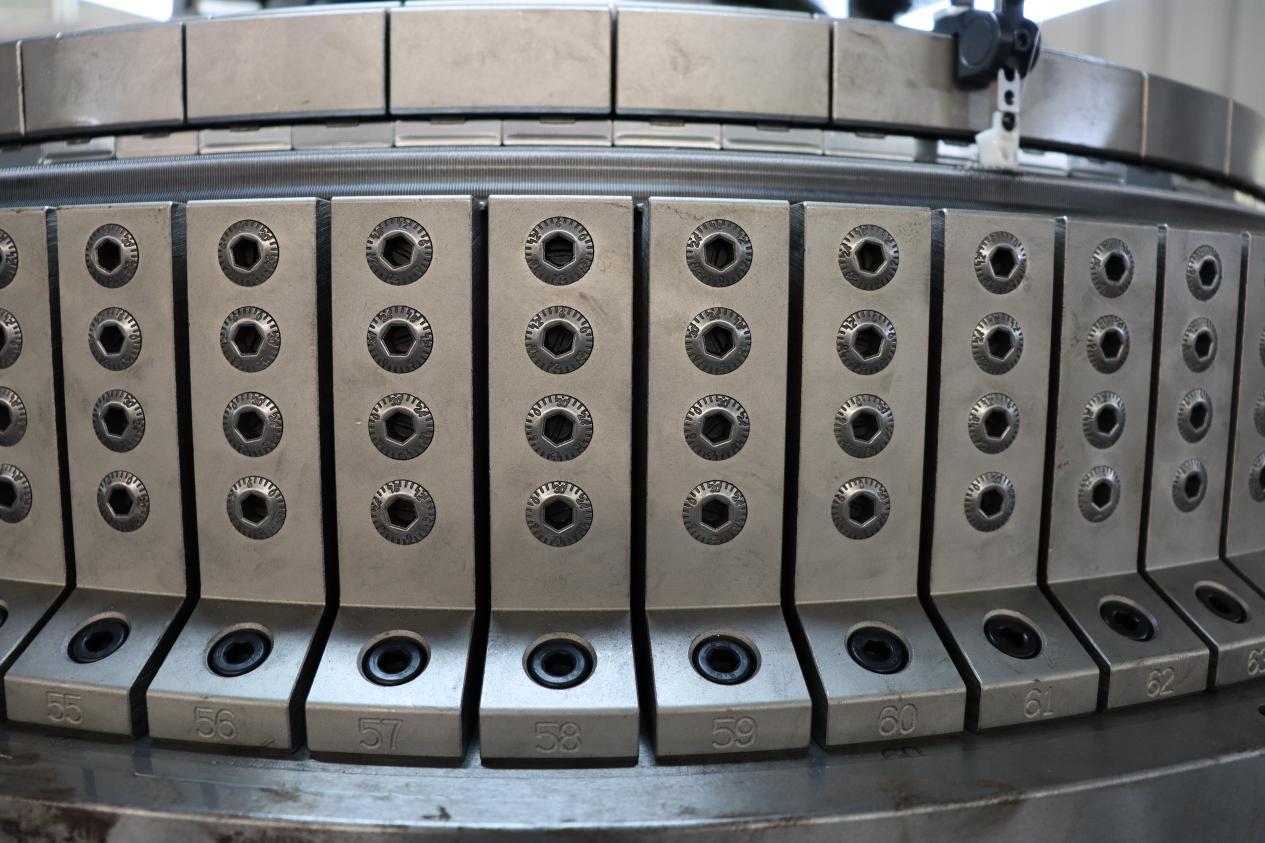

Body Size double Jersey Circular Knitting Machine equip with 4 track CAM on the cylinder which are 2 track knit CAM, 1 track tuck CAM and 1 track miss CAM. If you need 2 track CAM only, then Groz-Beckert needle can be changed to shorter needle.

The cylinder needle cam system for each feed-contained in a double replaceable section and having an exterior adjustment for the stitch cam slide.

Material of cylinder for Body Size double Jersey Circular Knitting Machine is stainless steel which is imported from Japan, which make sure the cylinder have high quality and good performance.

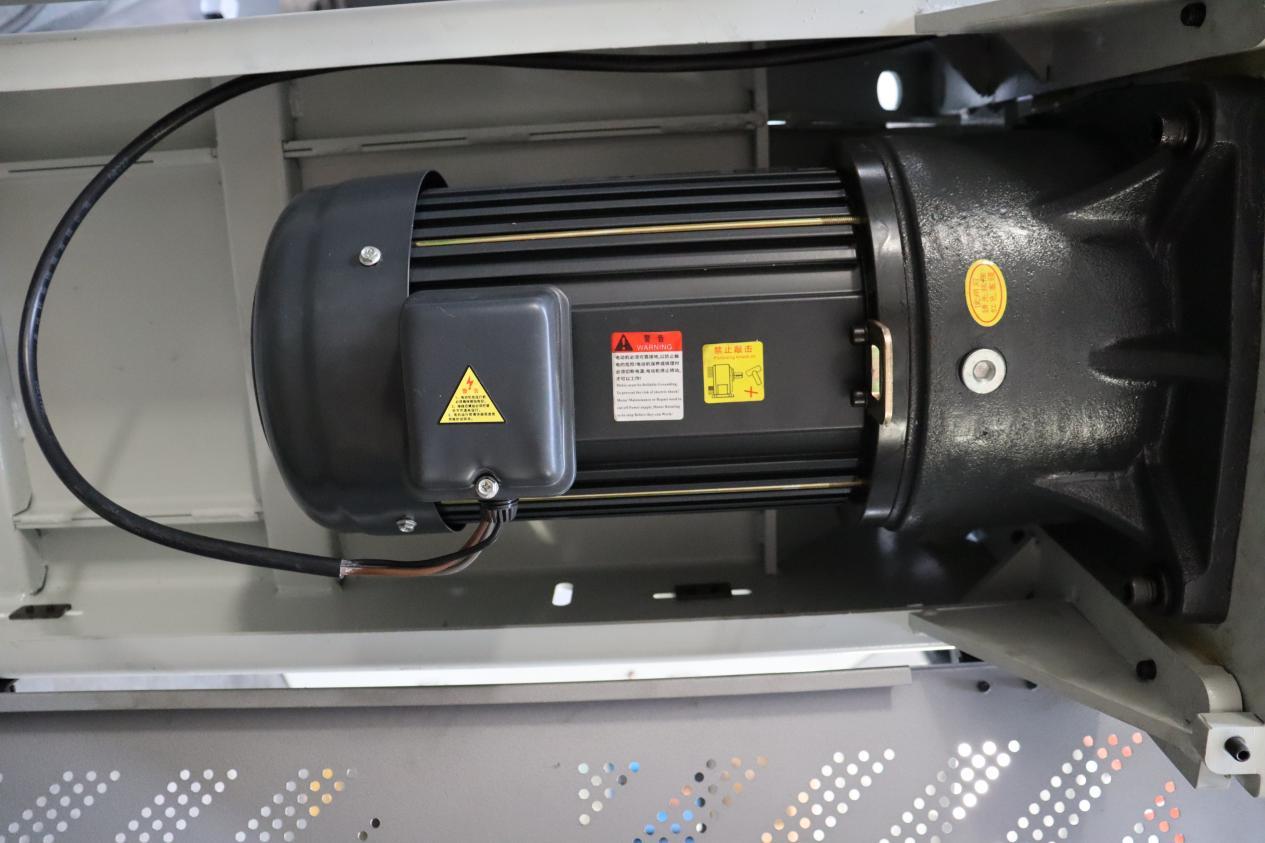

Components for drive system is made by superior material through high efficient heat treatment.

Gear and other main components are made in Taiwan and bearing are imported from Japan.

All of these guarantee the machine with high precision drive system, low running noise and stable operation.

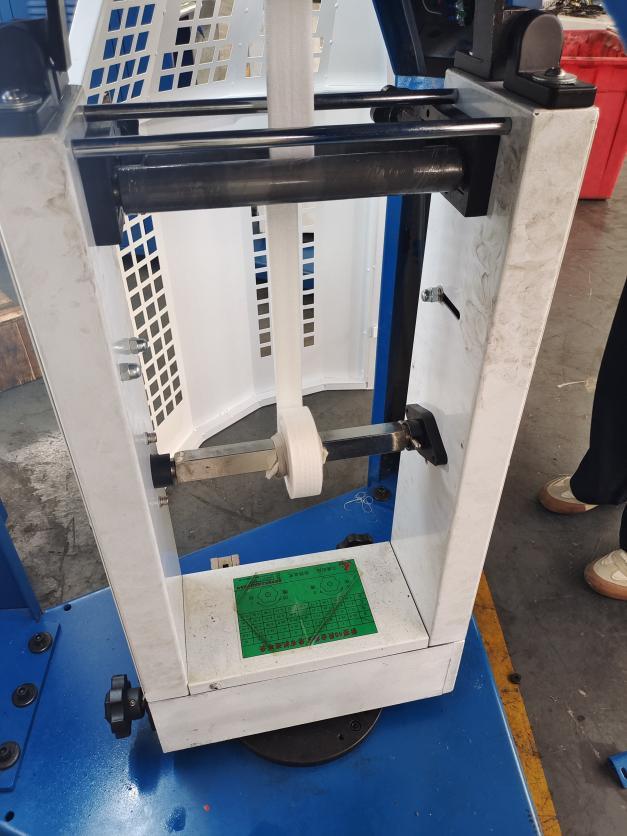

The big plate for Body Size double Jersey Circular Knitting Machine is made of steel ball runway structure, which make sure the machine with stable running, low noise and high abrasion resistant.