As the textile industry evolves to meet the demands of modern applications, 3D spacer fabric has emerged as a game-changer. With its unique structure, advanced manufacturing techniques, and diverse applications, this fabric is paving the way for innovation across various industries.

Composition: Advanced Materials for Superior Performance

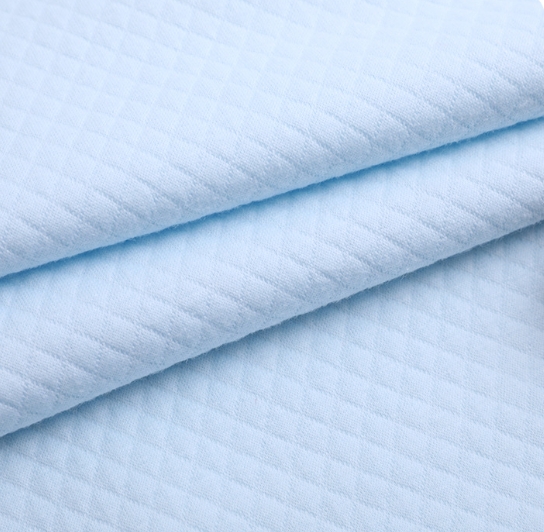

3D spacer fabric is crafted using a blend of high-performance materials such as **polyester, nylon, and elastane**. Its three-dimensional structure consists of two outer layers connected by spacer yarns, creating a breathable, lightweight, and resilient material. The open-cell construction enhances airflow, while the flexibility and durability of the materials ensure long-lasting performance, even under demanding conditions.

Manufacturing Equipment: Precision Meets Innovation

The production of 3D spacer fabric relies on state-of-the-art double jersey knitting machines and jacquard circular knitting machines. These machines enable precise control over fabric thickness, density, and design, allowing manufacturers to customize the material for specific applications. Key features of the equipment include:

High-speed operation for increased productivity.

Customizable settings for pile height and fabric texture.

Energy-efficient motors to reduce production costs and environmental impact.

The combination of advanced machinery and skilled craftsmanship ensures the consistent quality of 3D spacer fabric, meeting the highest industry standards.

Applications: Versatility Across Industries

The unique properties of 3D spacer fabric make it a go-to material for a wide range of applications:

-Sportswear and Activewear: Its breathability and moisture-wicking capabilities provide superior comfort during physical activities.

- Automotive Interiors: Lightweight and durable, it is used for seat covers and interior linings to enhance comfort and reduce vehicle weight.

Healthcare Products: Ideal for mattresses, cushions, and orthopedic supports due to its pressure-distributing and washable properties.

Outdoor Gear: Provides insulation and ventilation in backpacks, tents, and outdoor apparel.

Furniture and Home Textiles: Adds a modern touch to sofas, chairs, and bedding with its aesthetic appeal and functional benefits.

Market Outlook: A Promising Future

The global market for 3D spacer fabric is set to grow exponentially, driven by increasing demand for sustainable and high-performance materials. Industries such as automotive, healthcare, and sportswear are adopting this fabric for its ability to combine comfort, durability, and environmental benefits. As consumer preferences shift toward lightweight, breathable, and eco-friendly solutions, 3D spacer fabric stands out as a material of choice.

Why 3D Spacer Fabric Is the Future

With its advanced composition, innovative manufacturing processes, and wide-ranging applications, 3D spacer fabric is not just a product—it’s a solution for modern challenges. Its versatility and growing demand signal a bright future for manufacturers investing in this revolutionary textile.

Post time: Dec-30-2024