As an expert in the medical bandage knitting machine industry, I’m frequently asked about these machines and their role in medical textile production. Here, I’ll address common questions to provide a clear understanding of what these machines do, their benefits, and how they support the medical field.

1. What Is a Medical Bandage Knitting Machine?

A medical bandage knitting machine is a specialized piece of equipment designed to produce a range of medical textiles, including elastic and non-elastic bandages. These machines are essential for creating bandages with specific stretch properties, absorbency, and comfort. They’re engineered to ensure that each bandage meets medical-grade standards, offering high quality and consistency for patient care.

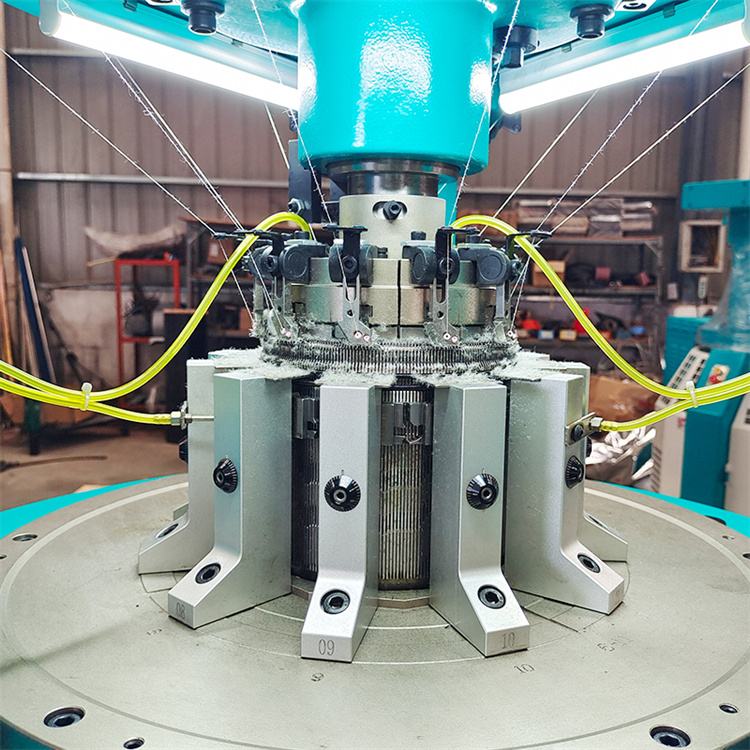

2. How Does a Medical Bandage Knitting Machine Work?

The machine operates by interlooping yarns through a circular or flat knitting mechanism. It can use a variety of fibers, including cotton, polyester, and elastic materials. Many machines are computerized, allowing operators to adjust tension, width, and elasticity levels, depending on the bandage's intended use. This precise control is crucial to producing bandages that meet specific medical requirements, such as controlled compression or flexibility.

3. Why Are These Machines Important in Medical Care?

Bandages play a vital role in wound care, compression therapy, and joint support. Medical bandage knitting machines allow for high-volume production of uniform, durable, and comfortable bandages. With reliable stretch and recovery properties, these bandages are essential in hospitals, clinics, and first-aid situations. By producing bandages with specific functionalities, such as elasticity for compression therapy, these machines support patient comfort and recovery.

4. What Types of Bandages Can Be Made with These Machines?

These machines can produce various bandages, including compression bandages, tubular bandages, and cohesive bandages. For example, elastic bandages, which are widely used for support and pressure, require specific tension and elasticity control. Tubular bandages, which fit snugly over limbs, are also crafted on these machines to ensure uniformity and comfort.

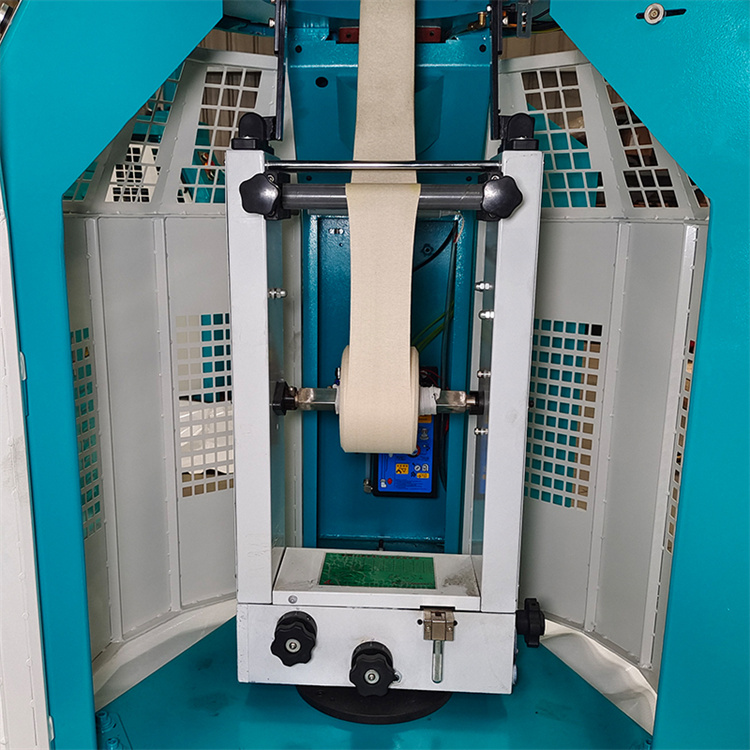

5. What Are the Key Features of a High-Quality Medical Bandage Knitting Machine?

High-quality medical bandage knitting machines are typically equipped with features like automatic tension control, adjustable width settings, and programmable pattern options. Advanced models may include monitoring systems to track production accuracy, ensuring each bandage meets strict medical standards. Additionally, machines that offer customizable options allow manufacturers to produce bandages that vary in size, stretch, and absorbency.

6. What Role Does Technology Play in Modern Bandage Production?

With advancements in technology, modern medical bandage knitting machines now feature computerized systems that improve efficiency and precision. These systems can store patterns, adjust settings in real-time, and even detect inconsistencies in fabric, ensuring high-quality production. This technology minimizes errors, reduces waste, and allows for faster production times, all of which are essential in meeting the growing demand for medical bandages.

7. What Are the Benefits of Investing in a Medical Bandage Knitting Machine?

Investing in a medical bandage knitting machine offers several benefits for manufacturers, including cost efficiency, high production speed, and customization capabilities. These machines enable manufacturers to meet specific medical standards while ensuring a consistent supply of essential medical textiles. Additionally, with customizable settings, manufacturers can diversify their products, expanding into various types of bandages to meet diverse medical needs.

8. What Factors Should I Consider When Choosing a Medical Bandage Knitting Machine?

When choosing a medical bandage knitting machine, consider factors such as machine speed, yarn compatibility, and customization options. It’s also important to look at the machine's durability, maintenance requirements, and user-friendliness. Some manufacturers may need machines capable of producing specific bandage types, so it’s essential to choose a machine with adjustable tension and width settings to meet varied needs.

9. How Can These Machines Impact the Future of Medical Textile Production?

The demand for high-quality, versatile bandages is rising globally, and medical bandage knitting machines will play a pivotal role in meeting this demand. With increasing advancements in automation and customization, these machines can cater to an expanding range of medical applications, from basic wound care to specialized compression therapy. As technology continues to evolve, these machines are expected to become even more efficient, further enhancing production capabilities in the medical textile industry.

Medical bandage knitting machines are essential for producing the wide variety of bandages needed in modern healthcare. These machines offer precision, efficiency, and adaptability, making them invaluable assets in medical textile manufacturing. By understanding the capabilities and advantages of these machines, we can appreciate their role in delivering high-quality products that support patient care and recovery.

Post time: Nov-11-2024